The importance of driving simulators in car development

AUTOMOTIVE 4 min read

In our previous episode, we explored the use of driving simulators in autonomous car testing. Now, we turn our heads towards car development. What is the importance of simulators in this field, and what are the requirements for such a system? Professor Bernhard Schick and DI Stefanie Trunzer from the Institute for Driver Assistance and Connected Mobility (IFM) – an institution of the University of Applied Sciences Kempten (Germany) – clarify.

Why are simulators so important for car manufacturers?

Designing new car models is very expensive and time-consuming. Especially the construction of physical prototypes slows down the process. Today’s advanced simulators enable to conduct many of the initial tests in the driving simulator. In this way, the maturity of the new car is a lot higher before the first prototype is created. If 70% or 80% of the work is done on a virtual prototype, this will save a huge amount of time and money on the car development costs. The simulators are therefore crucial to experience the driving, and all car manufacturers have several of them in their research facilities.

What do you at IFM (and especially the research group Adrive) focus on?

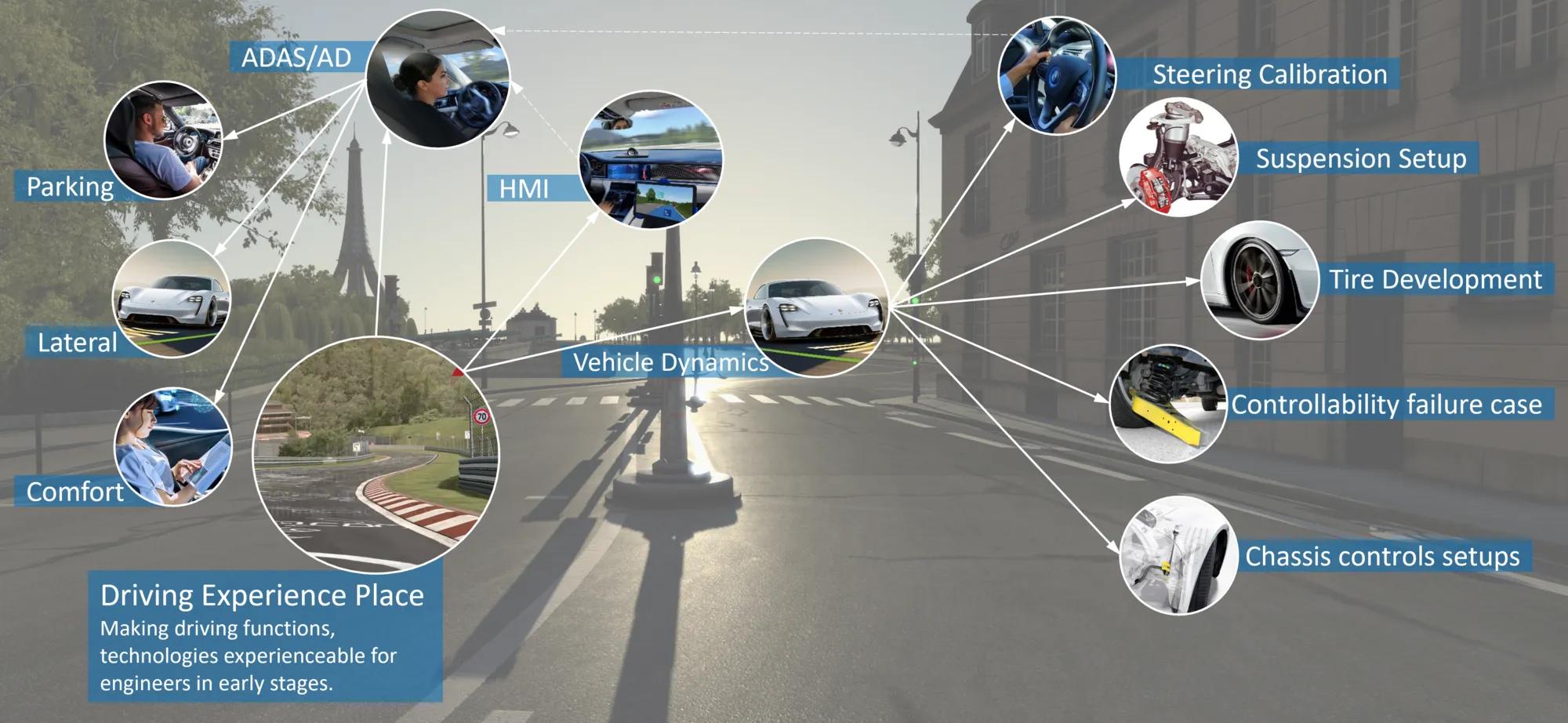

You could say that we are a method manufacturer. Our objective is to create the methods and tools for car manufacturers and their supplier to limit the number of prototypes. Because driving simulation is a big field, we cannot research everything. We focus on three main domains: ‘vehicle dynamics and controls with steering, tire and suspension application’, ‘controllability in failure cases’, and ‘ADAS/AD (Advanced Driving Assistance System / Automatic Driving)’.

Vehicle dynamics is all about bringing a huge amount of data to the simulator, so engineers can detect issues and make decisions very early on – sometimes a year before the first prototype is built. Steering, for example, is typically something that can be tested in the driving simulator. In many cases, the vehicle platform is known. The engine, body and thus mass distributions and stiffnesses may be different, but steering is often a carry-over system and available early. Engineers can do simulations with e.g. different tire sets, different weight, different suspension sets and apply the ECU parameters. This significantly lifts the quality of the first prototype – and shortens the time to market.

Another aspect is the ‘controllability in failure cases’. There, we test what happens if a certain mechanical or electrical part fails: is the failure for the driver recognizable and the car still controllable or not? If not, you need to look for redundant measures to ensure safety. This is very difficult to test on an actual moving car, both because it is very dangerous, and hard to perform (the part needs to break down during driving and this is hard to predict). Shifting this to the simulator will save a lot of time, money, and risk. In a next phase, we will also check the electrical failures.

Finally, we also conduct research on ADAS / AD systems. This is commonly split into Parking, Lateral control, and Comfort. A hot topic, for example, is the lateral control of level 1, 2 and level 3 systems: how is the quality of a car on a certain route? Often, engineers have to wait for the steering to be applied before they can start properly. This costs a lot of time. Once the steering specialist has reached his desired level of maturity on the simulator, LKAS (Lane Keeping Assist System) or aLDW (active Lane Departure Warning), for example, can be tuned before going into the vehicle. But this is only a small sample of what we can do.

Is sustainability a driver for the use of a simulator compared to physical testing?

The environmental drivers are limited. Cost saving and safety are the most important aspects here.

How important is the visualizations system for the simulator?

Obviously, it is very important. Not only the color reproduction, resolution and brightness performance of the projector. For us, the frame rate is absolutely crucial. In high dynamic driving it is obvious you need this high frame rate, for example when the car starts to yaw. But it is also a great addition in other use cases.

Obviously, it is very important. Not only the color reproduction, resolution and brightness performance of the projector. For us, the frame rate is absolutely crucial. In high dynamic driving it is obvious you need this high frame rate, for example when the car starts to yaw. But it is also a great addition in other use cases.

The upgrade from 60 Hz to 120 Hz was already a big step forward, but the move from 120 Hz to 240 Hz is just as big. Some say that from 50 Hz up the human eye cannot follow anymore so higher frame rates are unnecessary, but I can say this is not true. 240 Hz really makes a big difference. Test drivers that spend 8 hours in the simulator, for example, say it significantly reduces motion sickness and stress. Additionally, the more realistic the environment looks, the more trust people have. So, there are psychological issues as well.

You had a driving simulator on your previous campus, but decided to upgrade. What was the reason for that?

The screen was not big enough. Test drivers could always see the wall, which took away the realism. In our new building we have more space, so we decided to create a new one. We could not simply port the visualization system to a bigger screen, because we needed additional projectors. We took the opportunity to create a completely new system. When we tested the 240 Hz, we saw the improvement was significant. The response from the experienced test drivers was that they were less tired, and that they enjoyed working with 240 Hz. One of the big differences between Barco and the competition, was the much simpler handling of the projector.

This was the second episode of the interview with professor Schick. Click here to read the first part. If you have any comments or need information, please feel free to contact us.