Control rooms in the metaverse: science-fiction or just around the corner?

향후 검토 7분 읽기

Somebody once told me that everything we can buy commercially looks a lot less exciting when you work in an innovation lab. There is a lot of truth in that sentence. Take Barco, for example. Foreseeing and creating future possibilities of our current markets is the best way to stay ahead of the curve. That is why we meticulously follow emerging trends and technologies, trying to envision possible roadmaps for the next 10 to 20 years. One of the concepts on our list is the ‘metaverse’: the virtual environment that is expected to become the future of the internet. A technology ecosystem that will virtually mimic everything from the real world. While many people focus on the social and commercial aspects, it will also accelerate innovation for a lot of professional markets – including control rooms.

When Mark Zuckerberg, CEO of Meta (the company formerly known as Facebook), presented his vision of a metaverse, it didn’t really come as a shock to technology and science-fiction lovers like myself. It was the familiar surrounding we know from movies like ‘Ready Player One’, the Black Mirror episode ‘San Junipero’ or parts of the ‘Hyperion Cantos’ novel series – to name but a few. “It’s like a new version of The Sims” was another phrase I heard. And although the anticipated metaverse is a lot more than a computer game, this does show that people understand the concept easily, and that a lot of the technology is already available – just not capable of doing it on an all-encompassing scale.

Nonetheless, it did generate excitement to see a major company presenting this as the only true way forward. A lot of technology companies were particularly interested in this vision, immediately starting to look for future opportunities in this metaverse.

How near is the near future?

You probably can’t wait to start exploring this hyper-realistic metaverse. But you’ll need to be patient: it will take some time for this concept to materialize. There are still big challenges to tackle, as processing power is yet not up to the task to create an all-time present digital and virtual 3D world. And we haven’t even started to talk about connectivity: how will you tap into this virtual world? In science-fiction settings this is often done with a brain tap, but it can also be done with VR-goggles, large video walls or personal immersive spaces. The expected evolution is no different than the transformation of the internet: from the early concepts in the labs of the 1980s to the worldwide web we know today. The metaverse will need a similar roadmap that will possibly span multiple decades.

Digital twins: metaverse islands today

This does not mean we have to sit in a corner and hibernate for the next years. There are already some applications out there that can be considered metaverses. We’re talking about digital twins – digital environments that perfectly mimic the real world. Contrary to the future vision of Mark Zuckerberg, these are not connected to each other and act as ‘metaverse islands’, creating a universe within one application.

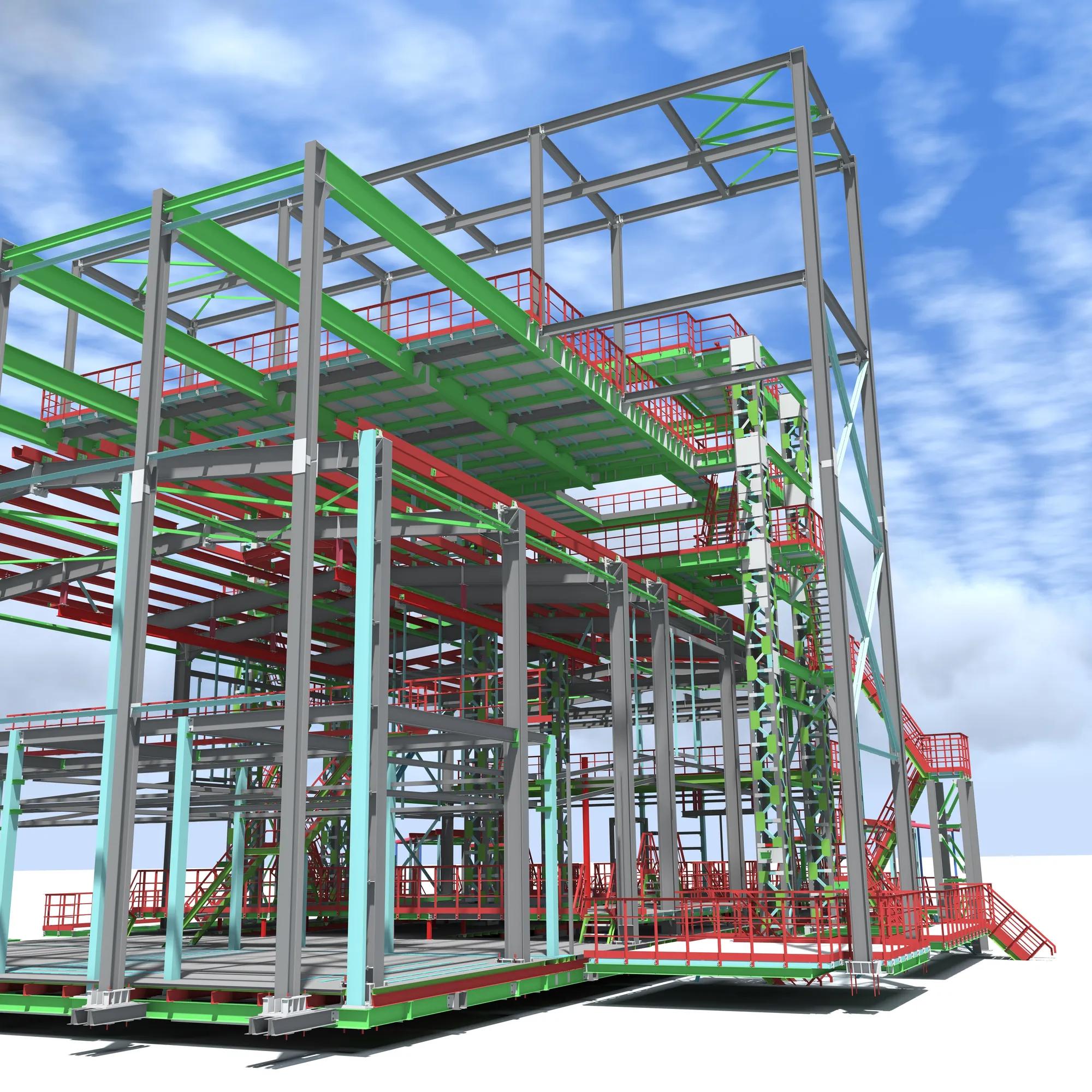

An example of such digital twins can be found in the manufacturing world. Complete factories are available in a digital version. This is often even not such a huge effort, as advanced processing plants nowadays are built using 3D CAD tools. A big part of the job is already done. With the 3D representations available, the designers can take the next step and simulate the real-time processes within the required boundaries.

Connecting with outside real-time data is then used to perfect the digital twin, for example to a changing context of temperature, humidity, quality of starting components, etc. In this way, a perfect digital twin of the complete factory is achieved, a “digital environment” through which you can navigate and acts exactly like the real-life “physical” counterpart.

Operational digital twins

There are already digital twins around – both in lab settings and in practical use. Barco participated in a 2019 research project from Ghent University (see video below). The resulting digital 3D-model could be considered a ‘metaverse island’. Another example is the collaboration between Siemens and NVIDIA, in which the pipes of a complete factory are simulated in a digital twin, so engineers can precisely predict the maintenance needs.

This opens up a world of opportunities. First of all, designers can easily simulate the effect of certain changes to the process, before implementing them in real life. Exploring safety and perfecting effectivity upfront, avoids costly alterations in the operational factory. Second, digital twins are also a great training environment, instructing new employees in all ins-and-outs of the factory, without disturbing the operations.

Metaverse opportunities for control rooms?

What does the metaverse mean for control rooms? Which possibilities do we see to ‘view better, share faster and resolve quicker’? The answer is: a lot. And we probably can’t even imagine the opportunities that will materialize once the metaverse really becomes fully operational.

Let’s list some topics to get the conversation started:

Simulation and training

Training operators is rather difficult today. Usually, newcomers sit at the side of an experienced colleague for a few weeks and learn by watching. The basics of crisis handling are explained, but most often no calamities arise during that training period. When a crisis really occurs, the operators are only theoretically trained and need to improvise most of the actions to perform.

A simulated operator training – much like the flight simulators used to train pilots – would without a doubt greatly contribute to better prepared operators, that manage to stay calm under pressure. The problem, however, is that all cockpits of a certain plane type look the same, but most control rooms are unique. Building a physical simulator is therefore not possible, but a virtual one in the metaverse is an excellent option. Creating such an immersive training environment would be a great asset to optimize operator training.

Another great advantage of a metaverse, is to let the operators explore the digital twin of the environment. In a factory, for example, it is often not possible to really get to know the plant in a safe and secure way, and browse around all aspects of the critical infrastructure. Having the time and possibilities to literally walk or even fly around in the factory’s digital twin to create a mental map is a great asset to take the appropriate decisions later, in the “physical” control room. Operators that have mental models of the operations make faster connections through what needs to be done when something goes wrong, or can even see ways to improve the process. In any of above circumstances, it is often wiser to first test a solution in the virtual environment, seeing how the system responds, than directly doing so in the real factory.

Monitoring

Data in a control room, represented in dashboards on big or small video walls, is quite abstract. It’s not always easy to assess the situation in the field by looking at displayed numbers, graphs and parameters. Stepping into a virtual live representation of the situation would help the operators to grasp the details more easily.

At the same time, they can also take a step back and get a helicopter view – creating a real complete situational overview. Just look at it as stepping into a virtual and dynamic version of Google Street View. Because there is so much data available, this digital representation can be extremely accurate. Different senses, even smell, can be represented in the metaverse in a digital way.

Collaborative problem solving

The metaverse is a social environment – as is a control room. This opens up a lot of additional possibilities for consulting external stakeholders when making important decisions. Imagine how efficient it would be to evaluate a certain situation together with experts, while being virtually “together as a team” and also “together on the spot”! This is exactly the kind of collaboration that would become possible.

When will you take your first steps?

If you think the metaverse will suddenly exist, and you’ll see a pop-up screen, saying ‘updating to metaverse’, you are in for a disappointment. It will be a long and winding road, with many detours. Some attempts will boom for a while and then disappear completely to make place for another hype-of-the-day. Expect a lot of fluctuations in the market (tip: invest in the attempt that offers the best user experience, not the best graphics).

Another thing to consider is that not every user will have the same interaction with the metaverse. Just like there are different types of browsers around today, there will also be different ways to browse the metaverse. This will depend highly on the user’s preference – and probably also on his or her budget. The same goes for the professional use cases. Some companies will be able to afford building a lifelike digital representation of their assets, others will need to settle with a lot less. But still the opportunities will be gigantic and we are really excited to be part of this evolution!

If you want to continue the conversation, please feel free to reach out to me.

About the author

Guy Van Wijmeersch

Guy Van Wijmeersch is Barco's Director Innovation & Design Thinking. He started with Barco in 1992 and held industrial designer and design director positions in Belgium, Germany and the USA. Guy holds a master degree in product design (Artesis University College of Antwerp) and a postgraduate degree of product design from University of Irvine, California, USA. He also holds a master degree in B2B Marketing, and is known for his innovation-centric thinking.