Creating a flat and seamless (video) wall is a science, not an art

LED 4 min read

Due to the seamless nature of LED video walls, the deployment is a very critical process. Every imperfection is visible. Especially when the pixel pitches are small, and the screens are intended to be viewed from up close, the tolerance is close to 0. The challenge for our TruePix design team was to come up with a solution that is deployed perfectly every time, by anyone, at any location.

Everybody acquiring an LED video wall has the same thing on top of the priority list: no seams. It is one of the main strengths of this technology, but no easy feat. Yes, an LED panel does not have a bezel and therefore the tiles can perfectly align. But to align the panels correctly requires a lot of skill, expertise, and patience. Patience to tweak the mounting structure so that it precisely fits. And the larger the wall, the more time is spent in adjusting. Leave too much space and there will be a seam, make it too tight and the result is even worse: visual inconsistency and a risk of LED damage.

For TruePix, Barco set out on a quest to make this process a lot simpler, so a perfect installation is not a matter of patience or luck, but a feature of the product.Our engineering team closely investigated every aspect of LED video walls, and located 5 areas with room for improvements. These are:

Perfecting the manufacturing process

A perfect deployment is only possible if your product is perfect as well. That’s why the first step is production. For the manufacturing of TruePix LED tiles, we developed a unique, patented, automated placement machine. This device positions the LED boards automatically on a very accurate location on the LED frame. In this way, we reduce the number of tolerance steps and avoid the inaccuracy inherent to the conventional manual procedure (using pins and screws). In other words, every LED panel that leaves the factory is of the same perfect quality, and 100% flat!

Smart mounting structure, created by smart engineers

What is so special about TruePix? You can summarize it to something we call ‘smart engineering’. Because engineers tend to consider themselves as pretty smart, this might sound like a redundant term. But when looking at the old way of working we must admit that not a lot of intelligence went into the video wall mechanics. If you know that no site condition is absolutely perfect (there is no such thing as a 100% flat wall or floor), you realize this has serious consequences for LED video walls. Especially when the pixel pitch is small, every imperfection is easily noticeable. That is why up to 30% of the installation time is spent adjusting these seams. And to make matters even worse, trying to create a perfectly flat video wall canvas from an imperfect wall introduces friction. And the sensitive LEDs hate that. Over 80% of LED installations are impacted by damages. That is why we put our smart engineers to work…

Two of the most basic laws of physics proved the solution: the force of gravity and the principle of communicating vessels. Using these concepts (and some 'smart engineering' of course) we came up with auto-balancing mechanics to neutralize imperfections of the underlying wall surface. A very unique and innovative idea, which is patented by Barco. The video shows how we use springs to assure an absolutely flat result.

Cabinet design

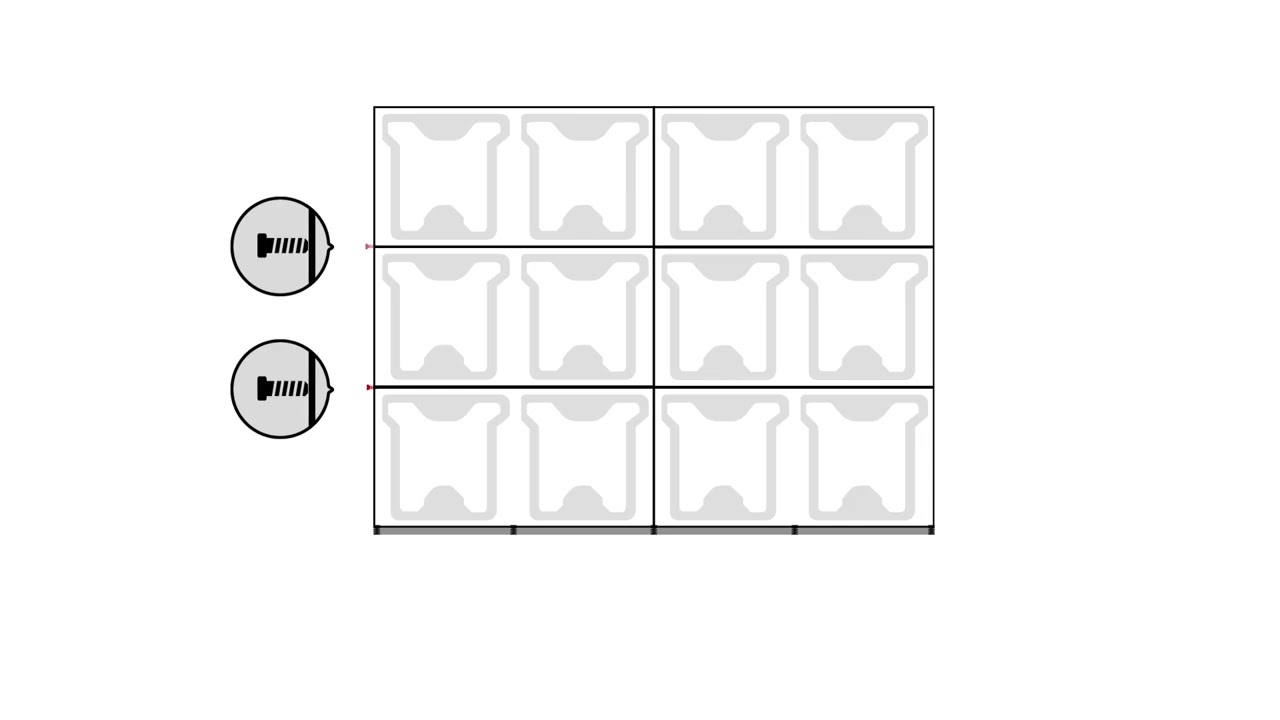

With another clever design innovation, TruePix eliminates possible seams between modules caused by machine imperfections on the mating parts. By letting the cabinet modules overlap with the module above, which means that the modules attach on the same cabinet, a so-called Z-step is avoided. The result is that the video wall surface is perfectly flat, uninterrupted by a seam.

Shift insertion for contactless installation

LEDs are sensitive components, especially when moving to smaller pixel pitches. Every risk of strain on the panels therefore needs to be avoided. This is very important during installation and maintenance. Using the Barco patented method of shift insertion, installers can introduce a new LED panel in a completely safe and easy way.

First you hang the panel on a guiding rod and click it. Then you only need a screwdriver to put the module in place. The video below will explain everything.

Hang in there, COALA!

The last section of this post is by no means the least. Or is it? We’re talking about a rather small device, called the Camera Optimized Automatic LED Aligner (COALA). And there is a lot to be said about this one! So much, in fact, that we will spend a complete post on it later in this series. For now, let’s just say it’s a system that uses 4 cameras to guide the installer, automatically making sure there are no seams and no pixel damages. It is mainly developed for the smallest pixel pitches, and absolutely unique. So keep an eye on this news section, for more in-depth info on TruePix – and COALA!